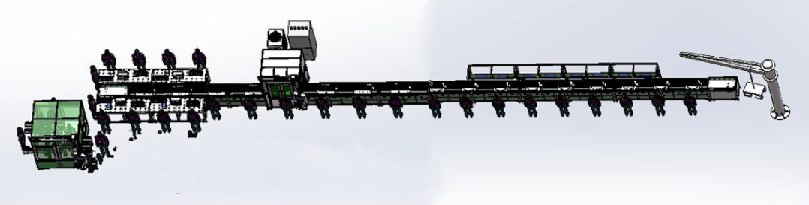

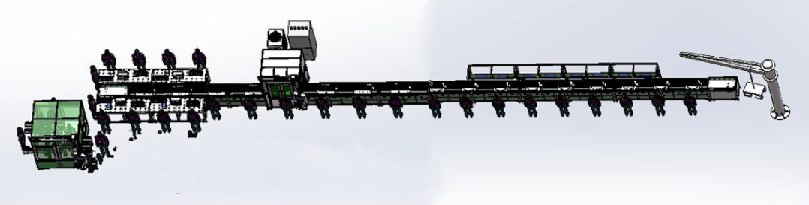

Energy storage battery PACK production line

The energy storage battery PACK production line is a production system that assembles a single energy storage battery cell into a complete battery pack (PACK) through a series of process steps.

1. Production line composition

Cell sorting equipment

Function: Detect and screen the key parameters of the cell, such as capacity, internal resistance, voltage, etc., to ensure that the performance of the cells assembled into the battery pack is highly consistent.

Cell welding equipment

Function: Connect the screened cells through welding process to form a battery module. Common welding methods include laser welding, ultrasonic welding, etc.

Module assembly equipment

Function: Install the welded cell combination into a specific frame or shell, and perform operations such as fixing and wiring to make it a complete battery module.

Battery management system (BMS) installation equipment

Function: Install BMS into the battery pack. BMS is responsible for monitoring the various status parameters of the battery pack, such as power, temperature, voltage, etc., and manage and protect the battery charge and discharge.

PACK packaging equipment

Function: To package the overall structure of the assembled battery module and installed BMS to form the final battery pack, which usually includes shell installation, sealing treatment and other links.

2. Production process

Cell preparation

First, the purchased cells are inspected for appearance and cells with obvious defects are removed.

Then the cell sorting equipment is used to conduct detailed inspection and screening of various performance parameters of the cells, and cells that meet production requirements are selected for standby.

Module assembly

Weld and connect the sorted cells according to the design requirements to form a cell module.

Install the cell module into the corresponding frame or shell, fix and wire it, and complete the assembly of the battery module.

BMS installation

Accurately install the pre-debugged BMS to the corresponding position in the battery pack, connect the relevant lines, and ensure that the BMS can work normally.

PACK packaging

Put the assembled modules and BMS installed components into the PACK packaging equipment, install the shell and seal it, and finally form a complete battery pack.

3. Key technical points

Welding technology

As mentioned above, the welding quality directly affects the reliability and conductivity of the battery cell connection. Therefore, it is necessary to continuously optimize the welding process parameters and improve the accuracy and stability of the welding equipment to ensure high-quality welding results.

BMS technology

BMS is an important part of the energy storage battery PACK. The quality of its performance determines the safety, service life and charge and discharge management effect of the battery pack. It is necessary to continuously develop more advanced BMS to improve its monitoring accuracy and the rationality of the control strategy.

Thermal management technology

During the use of the battery pack, the generation and dissipation of heat has an important impact on the battery performance and life. Therefore, it is necessary to consider how to reasonably design the thermal management system in the PACK production line.

粤公网安备 44030602007174号

粤公网安备 44030602007174号