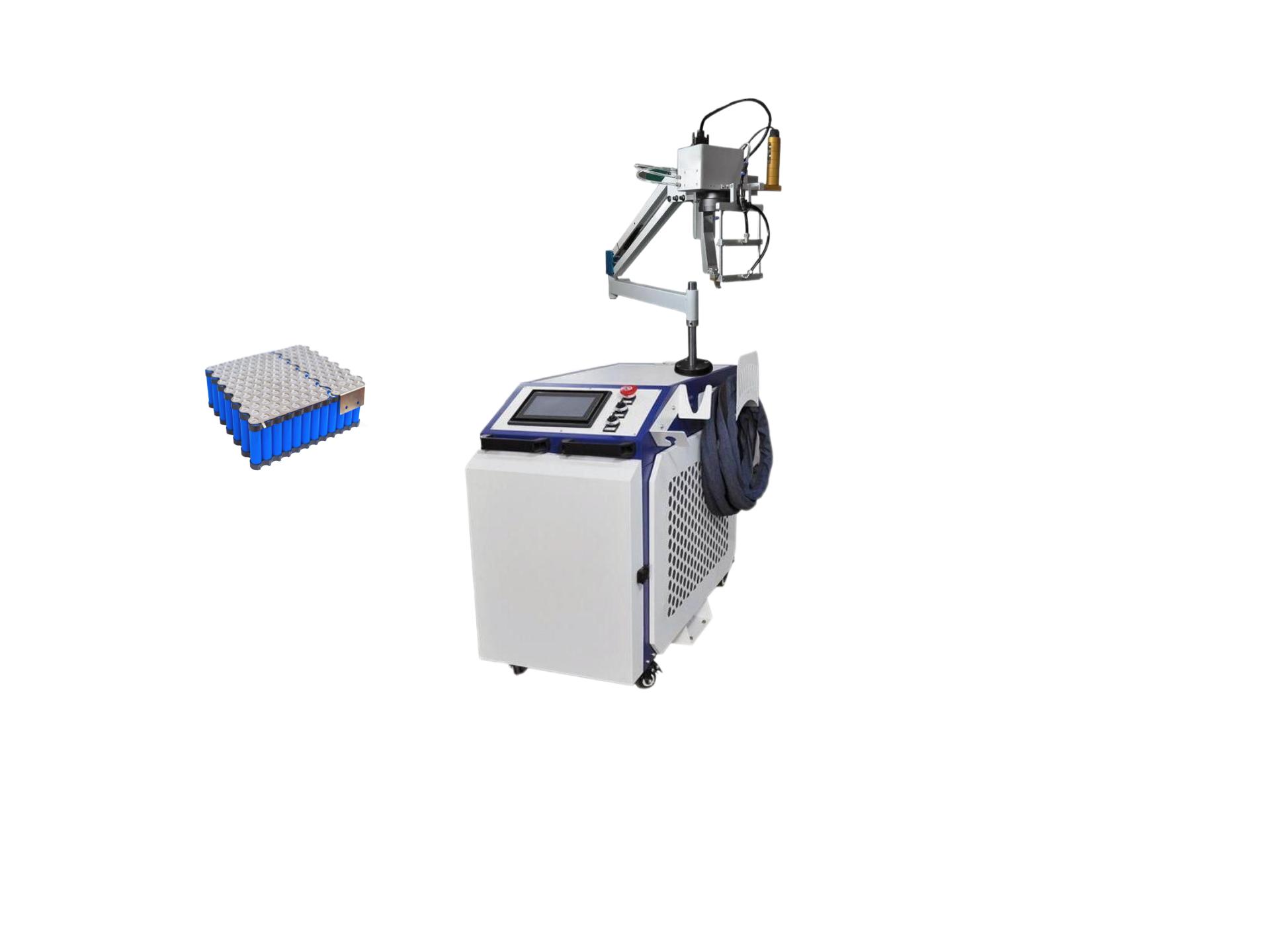

Lithium battery handheld cantilever laser welding machine

The lithium battery handheld cantilever laser welding machine is a professional welding equipment with important applications in lithium battery production and related processing fields. The following is a detailed introduction for you:

1. Equipment composition and characteristics

Handheld welding head:

It is convenient for operators to directly hold the welding operation, and can flexibly weld various components of lithium batteries, especially suitable for welding work on irregular shapes and special positions.

Its design conforms to ergonomics, and can be held for a long time without excessive fatigue, ensuring the continuous and efficient welding work.

Cantilever structure:

Equipped with an adjustable cantilever device, the cantilever can move, rotate and adjust the height in multiple dimensions.

This allows the welding head to cover a larger working area, which is convenient for welding lithium battery production equipment, modules, etc. of different specifications and sizes, without frequently moving the entire welding machine body, which greatly improves the flexibility and convenience of welding.

2. Working principle

Similar to the general handheld cantilever laser welding machine, it generates a high-energy-density laser beam and focuses it precisely on the lithium battery to be welded, such as the battery shell, connecting piece and other parts. The energy of the laser beam causes the metal material to melt rapidly to form a molten pool, and then during the cooling and solidification process, the various components are firmly welded together. During the welding process, the laser power, pulse frequency, pulse width and other key parameters can be finely adjusted according to the material characteristics of the lithium battery, the requirements of the welding part, etc., so as to achieve the ideal welding effect.

3. Advantages in the field of lithium batteries

High welding quality:

The laser beam energy is highly concentrated, and the heat-affected zone is extremely small during welding, which can effectively avoid thermal damage to sensitive components inside the lithium battery (such as battery cells, etc.), ensuring the performance and safety of the lithium battery.

The weld is flat, beautiful and has high weld strength, which can meet the strict requirements of lithium batteries for sealing, conductivity and other aspects of the welding part.

Fast welding speed:

Compared with traditional welding methods, the welding speed is significantly improved when used for lithium battery welding, which helps to improve the production efficiency of lithium batteries and meet the needs of large-scale production.

When batch welding of lithium battery modules, etc., the welding task can be completed quickly and the production cycle can be shortened.

Strong flexibility:

The handheld and cantilever design enables it to easily cope with various complex welding scenarios in the production process of lithium batteries, whether it is battery shells of different shapes or welding of connecting plates in a narrow space.

The welding head position can be flexibly adjusted in three-dimensional space, which is convenient for welding operations at various angles and parts of lithium batteries.

High precision:

It can achieve accurate positioning and welding of welding parts. For some delicate connection parts on lithium batteries, such as welding of pole ears and connecting plates, it can ensure the accuracy of welding and avoid welding deviations that affect battery performance.

IV. Application scenarios

Lithium battery production link:

In terms of welding and assembly of battery shells, the upper and lower shells can be accurately and firmly welded together to ensure the sealing of the shell and prevent the external environment from affecting the internal battery.

Used to weld the connecting plates inside the battery, the battery cells and connecting plates, and different battery cells are reliably welded through the connecting plates to ensure the smoothness and stability of the internal circuit of the battery.

Lithium battery module assembly:

The battery cells in the module are welded and connected so that each battery cell forms a complete module to meet the module's requirements for electrical performance and mechanical strength.

Welding the lead wires and other parts of the module to ensure reliable connection between the lead wires and the module, which is convenient for subsequent connection and use with external devices.

Lithium battery repair and modification:

When the lithium battery has a welding part failure (such as loose connection piece, cracking of the shell welding, etc.), the welding machine can be used for rapid repair to restore the normal use function of the battery.

For some situations where lithium batteries need to be modified and upgraded (such as increasing battery capacity, changing the connection method, etc.), flexible welding operations can also be used to achieve the corresponding goals.

V. Limitations and precautions

High equipment cost:

Compared with traditional equipment for lithium battery welding, its purchase cost is relatively high, which may cause certain financial pressure for some small lithium battery manufacturers or maintenance workshops.

However, in the long run, its advantages such as efficient production and high-quality welding can often make up for this cost gap in subsequent operations.

High requirements for operators:

Operators need to undergo professional training to master their operating skills, including accurate setting of laser welding parameters and stable operation of handheld welding heads.

Improper operation may result in poor welding quality and may even damage the lithium battery, affecting its performance and safety.

Strict requirements for the working environment:

The working environment should be kept relatively clean and dry to prevent dust, water vapor and other impurities from entering the laser welding area, which will affect the transmission and welding effect of the laser.

At the same time, during the welding process, attention should be paid to avoid strong light from damaging the operator's eyes, and corresponding protective glasses and other equipment should be equipped.

The lithium battery handheld cantilever laser welding machine has many advantages and important applications in the field of lithium batteries, but its limitations and precautions must also be fully considered during use to ensure that it can function efficiently and safely.

粤公网安备 44030602007174号

粤公网安备 44030602007174号